The Lean community should respond to the challenge that Toyota presented to itself and to the world: to prove that there are innovative and groundbreaking solutions on the journey to constant improvement and creation of value for the customer.

Womack Hits Hard

In a column published in August, 2017, Lean founder Jim Womack challenged the thousands of activists throughout the world who are trying to make Lean thinking into a widely-used managerial paradigm: Why hasn’t the promise been fulfilled? How can it be that academics, consultant companies, Lean facilitators (graduates of Toyota) and the many activists in the LGN network have still not managed to turn the principles of Lean thinking into a mass-use managerial paradigm?

This fundamental question leads us to questions about our current situation: Why isn’t the Lean movement rapidly gaining broad, deep influence throughout the world? Why are Lean tools applied primarily to improve existing systems, while only a tiny proportion of companies and organizations are involved in a systemic disruptive process to change their attitudes towards management and engage in a “Lean Transformation Formula”?

More Like the UN than Toyota

The Lean Global Network (LGN), which encompasses activists in 23 countries, isn’t really an organization at all; it is a decentralized, structure with no hierarchy that connects a wide variety of cultures, organizations, and individuals who have no common work language. All this makes it difficult to conduct a serious dialogue and raises several questions – who is authorized to determine a “Lean standard” for those who wish to change their perception of management? Can we construct a communications protocol that will serve as an accepted and agreed-upon standards? Is there playing experimental field (not a battlefield) on which it is possible to argue within accepted rules of the game and basic trust?

For me, the need to build a communications protocol is both the beginning of an action-based discussion, (and not a theoretical or academic debate) about fulfillment of the promise of the Lean movement and the opening volley for the development of a new “product” – the Lean New Global Architecture (LNGA).

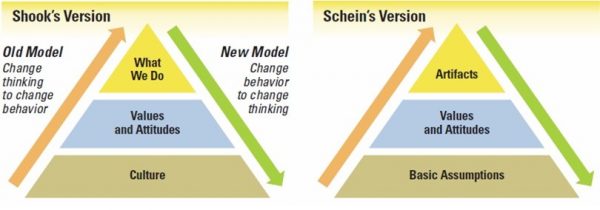

Below, we present three dilemmas that stem from Edgar Schein’s model for changing organizational culture, along with a similar version designed by John Shook:[1]

- Basic Assumptions (What are our basic assumptions? Why do we behave in a particular way?)

- Attitudes and Values (What is the basis for our actions? What is our “creed”?)

- Artifacts & Products (Customs, patterns, work habits, “Katas”)

As can be seen from the illustrations, the two versions suggest opposing directions for organizational change: Instead of changing patterns of thinking in order to change behavior, John Shook argues that it is preferable to change behavior and thus effect a change in thinking (and in the organizational culture). Is it possible to implement this in ourselves? I will try to make these dilemmas sharper as they come up in the global Lean community, since they all pose the same question: How and who determine the global standard – LNGA?

a. Basic Assumptions: Who determines and provides the interpretation and the connotation of Lean?

Every community or organization is predicated on basic thinking and agreement regarding what the members share in common and what they view as the best situation. Thus, for example, the basic assumption of the Lean movement is that creating value with respect is the foundation for creation of value (for the customer, the worker, and the community.) Moreover, we believe that the knowledge, principles and tools that we have developed are not privately owned; rather, they are in the public domain and belong to everyone.

As long as we maintain these assumptions, they raise several basic dilemmas:

How can we translate the element of developing people through “human respect” into an action-based value? How can it be balanced with other goals (such as generation of profit)?

b. Attitudes and Values

Every community or organization upholds articulated values and behavioral codes that stem from its basic assumption. The values serve as an agreed-upon code for determination of individual and public rules of behavior and decision-making.

Who is authorized to determine what these values (our “traffic regulations”), which are binding on the workers in a Lean Enterprise, are? If the knowledge is available to the entire Lean community, and has no single source, then anyone can say that he is “doing Lean” even if he is very far from the principles and the basic thinking of Japan (Toyota) and Boston (LEI). How do we set a communications protocol and a universal work standard for the LGN, when it is actually a mosaic of national institutes with local interests?

c. Activity and Behavior (What are we doing):

Laws and Regulations are never fully obeyed. It is possible to bridge the gap between the laws and actual behavior (Accountability) through instruction, education and training, as well as enforcement in special instances.

How will we establish means of enforcement and sanctions on those who stray from or break the rules in an organization that has no structure, values or language of communication? How can this be achieved according to an accepted set of values and behavior standards? How is it possible to build institutions or to establish principles of corporate governance in a voluntary virtual open system?

How will a standard for decision making be defined so as to benefit the entire community? In an international system, what will serve as the function authorized to decide on the means of enforcement available to the network? How will intellectual property be preserved in a network that is available to all?

The Value Creation Architect (VCA) role and responsibilities

As the VCA for developing the LNGA standard, my role is to build an evolutionary process based on global competition and inclusive groups of participants.

As someone who has been involved in problem-solving, I know that first I have to understand, map and define the current situation – even if it is difficult to identify. According to my research methodology for the identification of means of action in the creation of an LNGA work standard as the basis for dissemination of the Lean viewpoint, we must create an hackathon, a space for public debate within the community, in all its diversity, and provide an “experimental library” – an ecosystem lab open to anyone who wants to be active, take initiative and develop teaching tools – in order to encourage and support learning through open experiments and development of a facilitation methodology based on Lean principles.

By choosing to open a public discussion about development of Lean principles, I want to exchange the hierarchical centralized source of authority with a dialogue or fruitful struggle between proven ideas and work methods. Whatever survives the completion and can serve as a force for emulation, will become the accepted standard in the Lean community – until someone else disrupts and develops a new and better standard.

The Lean community should respond to the challenge that Toyota presented to itself and to the world: to prove that there are innovative and groundbreaking solutions on the journey to constant improvement and creation of value for the customer.

Boaz Tamir, ILE.

Leave a Reply